Fab Valve Launch

June 13, 2019 | Posted By Romahlio Williams

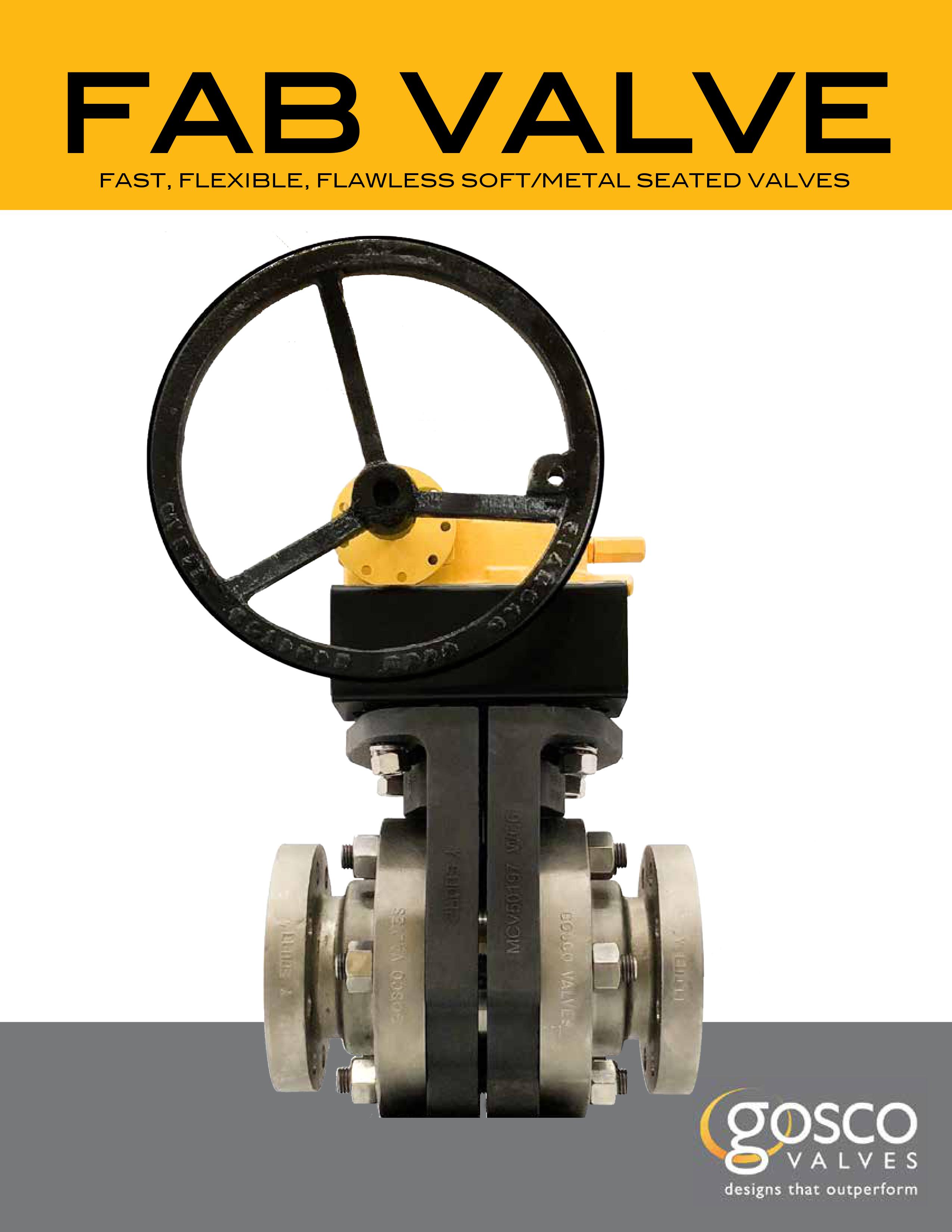

Fabricated, fabulous design for exotic alloy valves.

Gosco is pleased to launch the new Fab Valve product line. It is a metal and/or soft seated valve aimed to serve the severe service valve market, specifically for high alloy applications.

The Fab Valve is offered in Class 150, 300 and 600, and up to NPS 6, standard port. It uses common internals for all pressure classes, and by machining only four components (body, bonnet and end connections) in any Fab Valve, you can change the pressure class, end connections, port size AND/OR the materials of construction – including exotic alloys. Take a look at the Gosco website to see how that can be done: http://goscovalves.com/fabvalve/#alloy/

Here are some great features you would like to know:

Size: NPS 1/2 full port to NPS 6, SP

Pressure Class: Class 150, 300 and 600

Temperature range: -50ºC/-58ºF to 593ºC/1100ºF.

• The most corrosive resistant spring material on the planet is Inconel 718. We matched all the internals of the Fab Valve to the springs.

• We have proprietary horseshoe plates that never come in contact with the process media. They are designed to bolt all the components together.

• We use the same Boronized Inconel 718 trim sets as our M-Class line – in fact, they are interchangeable.

• It is a truly bi-directional ball valve with no “preferred direction”.

• We offer an arcuate cut ball design to reduce the velocities in the first/last 5 degrees of opening/closing. This extends the life of ball and seats.

• There are endless Vari-V ball options for control applications.

• Any alloy option you can name, we can deliver.

We are taking orders now for the Fab Valve, and will ship in 18-20 weeks. That lead time will decrease as we bring in inventory, and will soon have an 8-10 week lead time. The Fab Valve is available to all current distributors on a NON EXCLUSIVE basis.

News Archive

-

SIS Named Exclusive Distributor…

August 12, 2023 -

Gosco Valves Grants Exclusive…

October 28, 2022 -

Kinetrol Launches Brand…

August 12, 2022 -

Fab Valve Launch

June 13, 2019 -

Updated Website

January 18, 2019